Warm Forging

Warm forging is performed at temperatures between room temperature and the recrystallization temperature of the metal. It combines some of the benefits of both hot and cold forging, such as:

- Reduced forging forces required compared to cold forging

- Enhanced formability

- Minimized risk of work hardening

- Better surface finish and dimensional accuracy compared to hot forging

Cost-Saving Advantages

Warm forging offers several cost-saving advantages, highlighting its increasing use as a manufacturing method. The temperature range for warm forging steel extends from just above typical household oven temperatures to below the recrystallization temperature. This range is approximately 800 to 1,800 degrees Fahrenheit, depending on the alloy. However, a narrower range of 1,000 to 1,330 degrees Fahrenheit is emerging as particularly commercially viable for warm forging steel alloys.

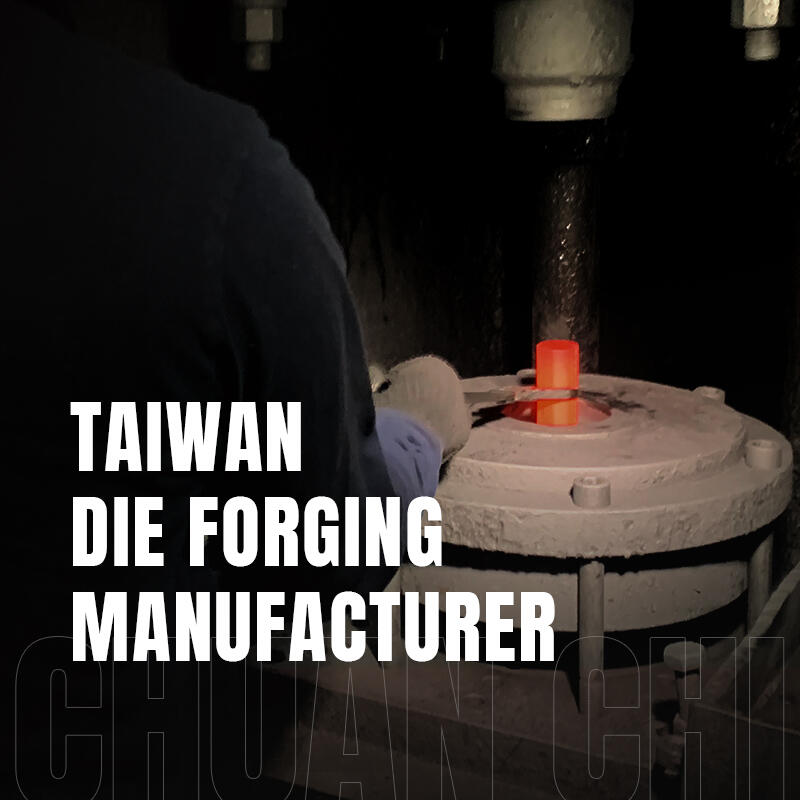

Warm Forging Example

Advantages of Warm Forging Compared to Cold Forging

Warm forging offers several potential advantages over cold forging, including:

- Reduced tooling loads

- Reduced forging press loads

- Increased steel ductility

- Elimination of the need to anneal prior to forging

- Favorable as-forged properties that can eliminate the need for heat treatment